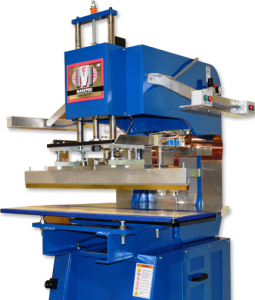

Radio Frequency Bar Welders

Order a Bar Welder View All Equipment

MarkPeri has been providing reliable, cost-effective RF welding solutions since 1982. Our many years of relevant application experience and unsurpassed market knowledge enables us to offer the ideal RF welding machine and equipment for your needs.

We offer sizes from 36” to 72” wide Bar lengths. We can offer them in 6kw to 20kw for sealing wider widths. These units are designed with the smallest footprint due to having our generator under the machine. They can be used to seal long seams for tarps and liners made of materials such as PVC mesh, vinyl or other polyethylene materials.

We can offer custom mounting of start buttons and an attachment for punching out grommets prior to welding. If you are searching for a trusted and reliable RF welding equipment supplier, MarkPeri is the go-to source for all of your industrial Radio Frequency Equipment and 3KRF sealing needs.

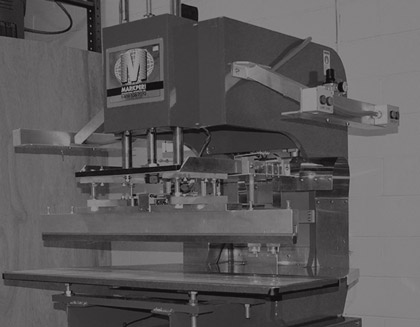

Used & Refurbished RF Bar Welders Available

If you’re looking for a great value on an RF bar welder, consider purchasing a used or rebuilt machine from MarkPeri. We specialize in rebuilding all types of RF machines, which we then offer for sale at extremely affordable prices. We refurbish bar welding equipment to like-new equipment, ensuring it will serve you well for a long time to come. We also provide reliable repair service to keep your RF bar welding machine on the job and minimize unproductive downtime.

Bar Welders for Tarp, PVC, and Vinyl Welding

MarkPeri can meet your bar welding equipment requirements. Whether you need industrial tarp welding equipment or a PVC welding machine, MarkPeri can create custom configurations to tackle your specific precision sealing needs. For more information on custom configurations, talk to a MarkPeri team member today at 516.208.6824.

Bar welders are used to seal long seams for tarps and liners made of materials such as PVC mesh, vinyl or other polyethylene materials. A hot bar welding process is typically used to enjoin the thermoplastic films that comprise these products. This process employs the principle of pressing two thermoplastic films against a heated bar (or bars) to soften them and create a seal. Depending on the bar welding process, one or two metal bars may be used to form the seal. When two bars are used, they’re deployed on either side of the films. One of the bars is hinged to facilitate the placement and removal of the thermoplastic films.

RF Bar Welding for Tarpaulins and Truck Tarps

A popular type of bar welding technique uses radio frequency bar welders. An RF bar welder employs the same basic principles found in a common microwave oven. The RF bar welding machine generates radio waves that create heat inside the fabric via molecular action. The molecules that comprise the plastic are essentially flipped from a positive to negative electrical charge at a rate of several thousand times per second. This process generates friction from inside the fabric that is transmitted to the outside. The combination of the heat produced by the friction and the pressure generated by the bar dies creates a seal that bonds the plastic layers together. RF bar welding is often used to produce truck tarp seams. The bar seal welds the tarp’s fabric panels together in much the same fashion as a sewn seam.

Benefits of Radio Frequency Bar Welders

RF Bar Welding equipment presents many benefits over other welding options. These benefits include:

- Environmentally Friendly: An RF bar welder does not produce smoke during the sealing process, making it an environmentally friendly option for any manufacturing operation.

- Minimizes the Possibility of Damage: Most of the thermoplastic materials used to produce tarps and liners offer good resistance to the RF heating technology, making the process safe and minimizing the possibility of damage.

- Prevents Adherence of the Plastic: A coating of polytetrafluoroethylene (PTFE) can also be applied to bar surfaces to prevent adherence of the plastic.

- Superior Quality: Overall, RF sealing produces the best quality in terms of bonding and appearance of the fabric.

Get More Information Regarding Our Bar Welding Equipment

Whether a brand-new or used/refurbished RF bar welder best meets your needs and budget, you can count on the experts at MarkPeri to help you choose the right machine for the job. Contact us to learn more about our top-quality bar welding equipment today by calling or contacting MarkPeri. We’ll do our utmost to assist you!