Considerations for the RF Welding Design Process

Before you can begin the production process, you must gather the key information in order to facilitate an accurate and expeditious product assessment.The design process can be very involved and complex. The first step in product design is the understanding of the intended application and functionality specifications for the product.

If possible, find example of the products, including photographs. Identify the required features of the product for the end-use environment and any regulatory agency guidelines required for product, where applicable.

Request A Quote Click to Call 516.208.6824

The Design Process For RF Welding Applications:

1. Decide The Product’s Intended Function

The first facet in determining if your product is RF weldable is to identify its intended function to determine if it can benefit from radio frequency welding. Pressure is a factor when assessing the use of an RF weld. A product that must contain highly compressed air and interior pressure that exceed certain levels will fail the criteria for RF welding because some welds will fail under the intense pressure. Products that must withstand abrasion require heavier reinforced fabric to endure RF welding.

The product may also need to meet material ratings as specified by agencies such as FDA, USDA, NSF, NFPA or other specific ratings.

2. Determine The Product’s Dimensions

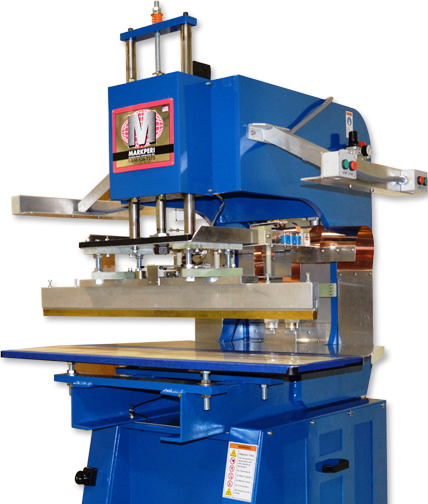

You will also need to consider the dimensions of the products that need RF welding. Radio frequency plastic welding machines operate like a punch press or printing press, which could be a problem for large products. The largest custom RF welding machines have the capability to weld mattresses.

Make sure that you choose an RF welding company that has the equipment to work efficiently with your product. Large products like landfill liners, truck tarps or tent tops may require up to hundreds of bar welds to form the long seams and edge hems.

3. Configure the Product

Generally, radio frequency welding consists of a two-dimensional process. However, designers can create more complex products with perpendicular seams — the key determinant being the configuration of the product. The process employed to fabricate three-dimensional products consist of two-dimensional steps, completed one at a time. Nonetheless, if you cannot configure a three-dimensional product utilizing a progressive two-dimensional process, the complexity of the product may make it unsuitable for RF welding.

4. Create Drawings (CAD)

You will need to develop professional drawings for your product. The best way to convey the concept of your product is with CAD drawings. Although the drawings do not need to be three-dimensional, they will need to communicate the product you would like to manufacture.

5. Contact a Company That Specializes in RF Welding

Make sure to choose a company that is able to work with your materials and meet your product’s requirements before you take further steps moving ahead with manufacturing products that use radio frequency welding. Discuss the specific needs for your project, such as size, functionality, material preferences, production methods, production schedule and deadlines.

6. Develop a Prototype

You will need a prototype of the product, which provides a starting point for determining if the design will work or seeing features that the designer may need to rework or change. The prototype may or may not meet all the requirements of the final product.

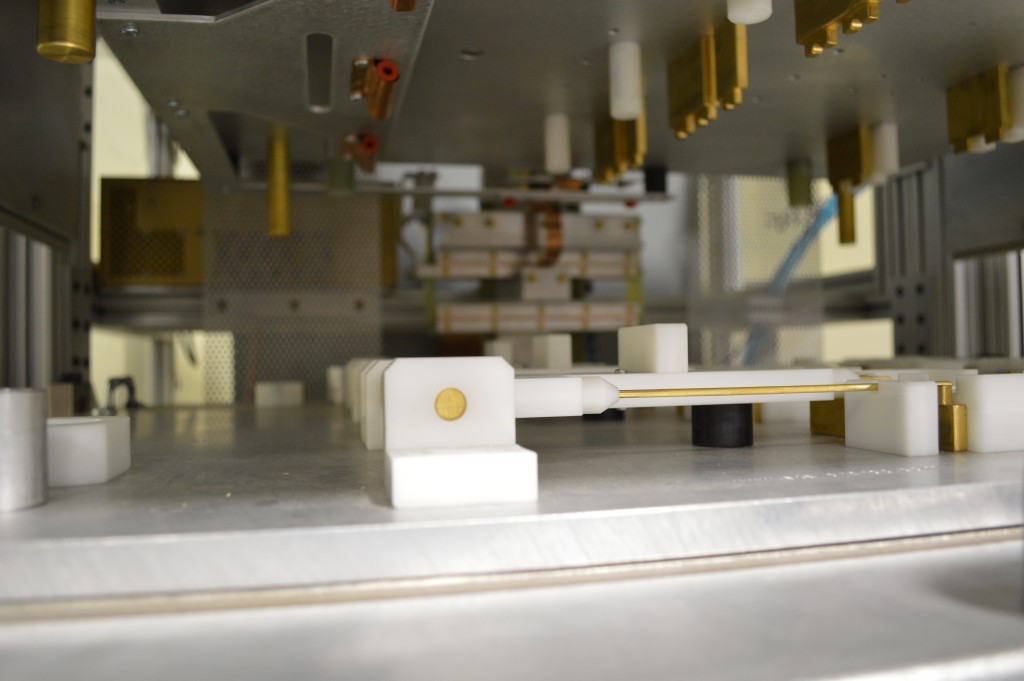

7. Establish Tooling Die Requirements

Once you’ve chosen your preferred material and fabrication methods, you will need to establish if any tooling or dies are needed to manufacture the product. Tooling can represent a significant portion of the project and needs to be addressed during the early stages of planning.

8. Rework the Design

Once you evaluate the prototype to determine what works and what does not work, you have the information you need to determine if you need to rework the design or the material or improve functionality. After you complete this step in the process, you can proceed to the production of the finished product. This part of the process can require multiple reworks and requires patience and focus on the end objective for the finished product.

Work With The Experts at Mark Peri Today

Now that the product design meets the specifications, it is time to move forward with the production run! Collaboration with a radio frequency welding expert that can evaluate your product requirements and provide recommendations and manufacturing options will ensure that you have a quality product that will meet or exceed your expectations.

Questions? Contact MarkPeri today and our RF welding experts will help answer your sealing questions.