Radio Frequency Welding & Dielectric Sealing Machines

RADIO FREQUENCY WELDING MACHINES

Order a Dielectric Sealing Machine Click to Call 516.208.6824

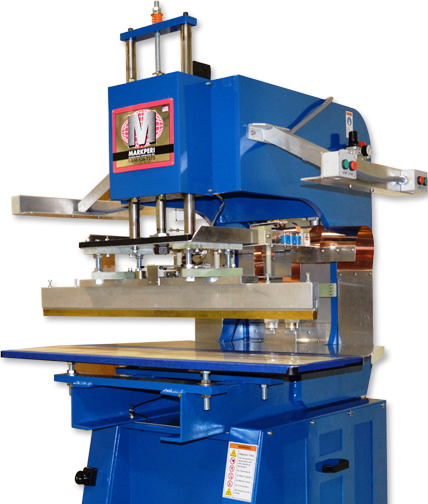

When you’re looking for access to top-quality radio frequency welding machines, also called dielectric sealers, MarkPeri is the comprehensive source your business can count on.

We manufacture an impressive range of RF plastic joining machines representing the cutting edge in the industry. We also provide an extensive inventory of dielectric / RF welding machines from other top U.S. brands. From helping you choose the right material for your rf welding application to machine consultations, you get the selection you want along with customer service and product support dedicated to your complete satisfaction..

MARKPERI RF Welding Machine & Dielectric Sealers

Since 1981, our in-house team of electrical, mechanical and RF engineers have been using cutting-edge machines and innovative techniques to advance RF plastic welder technology. With hundreds of machines ranging from 1/2kW to 100kW and combined warehouse space in excess of 40,000 square feet, we offer both turnkey products and tailored solutions based on your specific needs. We have the ability to custom design, modify or adapt radio frequency welders and dielectric sealers for optimal performance no matter the size of the operation or type of application.

If you’re in the industrial packaging, automotive or medical industry, having the right dielectric welding machine is an operational necessity. Our dielectric welders and RF heat sealers represent exceptional performance and superior energy efficiency. They help you manufacture better products with stronger seals capable of withstanding regular wear and tear and heavy use. You’ll find the following types of RF welders within our inventory:

Bar Welders — Our MarkPeri bar welders come in 36-inch to 72-inch-wide bar lengths and offer anywhere from 6kW to 20kW power output. Commonly used for sealing long seams found in products such as tarps and liners, our bar RF welding machines for sale feature an exceptionally small footprint, custom mounting of start buttons and a special attachment for punching out grommets for a smoother welding process.

Small Footprint RF Machines — When space in your production facility is a concern, no other RF welder manufactured in the U.S. is as compact as our small footprint machines. A powerful 25kW version of our reliable 4kW design, this RF plastic welder has helped countless businesses in the automotive and medical industries improve productivity no matter the physical constraints.

Double Cycle TTBL Machines — Our double cycle RF welding machine delivers ultimate performance and reliability while eliminating the need for additional processing equipment. With a small footprint, this 10kW generator features a stepper motor-controlled double-cycle switch. You get a durable RF welder for plastic that’s suitable for a wide variety of medical applications.

REFURBISHED RF WELDING / DIELECTRIC MACHINES

If you’re searching for a more affordable way to buy radio frequency welding equipment, MarkPeri is a full-service supplier capable of rebuilding all types of machines. We offer value in the reconditioned market by delivering quality and selection along with dedicated customer service, product knowledge and support. Our team of experienced technicians take great care in restoring radio frequency welding machines to “like new” condition. All refurbished RF welders for sale come with a six-month factory warranty.

GET IN TOUCH TO BUY RF WELDING EQUIPMENT TODAY

MarkPeri is home to the widest range of RF welders for sale for your automotive, industrial or medical applications. We manufacture and sell bar welders, small footprint RF machines and double cycle TTBL machines capable of unlocking the full potential of your operation. Whether you need a cost-effective used or refurbished option or a custom-configured plastic welding machine or additional rf welding information, you’ll find it here. Give us a call for more information and to place your order today!