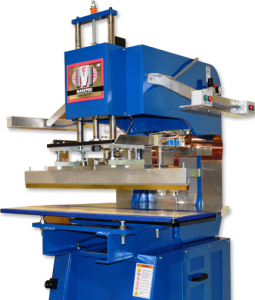

Traditional RF Sealing Technology

Get a Quote for a Traditional RF Sealing Machine Click to Call 516.208.6824

Markperi is a leading manufacturer of traditional RF machines ranging from 1.2kW to 100kW. Our ability to manufacture cutting-edge RF welding equipment comes from the team of skilled electrical, mechanical and RF engineers that are constantly pushing the envelope in developing state-of-the-art solutions.

No matter the type of product or size, or your budget, we have the technology to exactly meet your RF sealing equipment requirements. MarkPeri offers a broad selection of traditional RF welding equipment which includes stand alone, shuttle systems and Turntables for higher production rates. We can offer custom design to deliver equipment that’s designed, modified or adapted to your specific needs.

Industry Applications

MarkPeri radio frequency sealing equipment can handle multiple applications across various industries. Our extensive experience allows us to develop the most optimal solutions for your heat-sealing needs, regardless of your operation size or type. Implementing one of our RF sealing systems into your manufacturing process will increase efficiency and production levels.

Industrial Manufacturing

MarkPeri radio frequency sealing machines are valuable assets in manufacturing sealing applications for various high-quality products. Many industries depend on our RF equipment when they need secure, leak-proof seals. RF seams are long-lasting and ideal for applications that require heavy use and high resistance against wear and tear.

Typical packaging applications include everything from clamshell and blister sealing to loose-leaf binders and plastic boxes. Our RF sealing equipment works fast and effectively, whether you make checkbooks, photo albums, ID tag holders, inflatable toys, pool liners or camping accessories.

Automotive Applications

Many products in automotive manufacturing require radio frequency sealing to ensure safe, long-lasting performance. RF sealing allows manufacturers to make parts that are higher in quality, more visually appealing and safer for consumers. Our equipment can optimize your fabrication process with lower energy consumption, material loss and cycle times.

MarkPeri RF equipment can seal automotive parts like door panels, heel pads, floor mats, airbags, sun visors and more. Whether you’re exploring RF equipment for the first time, upgrading older machinery or expanding your manufacturing capabilities, we have everything you need. We can even deliver a custom solution specific to your operation.

Medical Products

Medical manufacturers can produce high-quality products with radio frequency sealing systems more efficiently than many forms of conventional heat sealing. Our machines ensure that each product has a solid, dependable seal, making it safe from leakage, contamination and other issues. Manufacturers can make specialized medical products that meet the industry’s health and safety demands by using MarkPeri sealing systems.

The medical industry depends on our 3KRF technology welders for sealing applications that use materials like EVA, PVC, polyethylene and polyurethane. This sealing equipment reduces welding times and power consumption while delivering enhanced precision when manufacturing items such as blood bags, pressure cuffs, blood separation systems, in vitro feeding bags and many other medical products.

Benefits of Traditional RF Sealing

Traditional RF sealing produces leak-proof and airtight seals by combining the strengths of the joining substrates, making the bond as durable as the original materials. The joint is heavy-duty and highly resistant to rips and tears, producing a seam superior to traditional bonding methods.

RF sealing is optimal for producing the most durable seams in heavy-use applications under harsh conditions.

Some of the primary benefits of using MarkPeri RF sealing equipment include:

- Exceptional strength: Traditional RF sealing creates a stronger seal than the actual materials. The result is a tighter, more durable bond that’s less likely to tear apart, break or crack. Better seals mean improved resiliency and higher product performance.

- Outstanding adaptability: RF sealing is a highly adaptable process that can bond two materials with different compositions. This ability provides much more flexibility in manufacturing processes with diverse specifications.

- Airtight security: Radio frequency seams are among the most durable and secure options for plastic products needing airtight and weather-resistant sealing. These seals offer superior protection to items requiring the highest levels of security.

- Cold-running equipment: Compression happens while the equipment runs cold, allowing more control over the seam and creating a higher seal strength. Less heat also means damage is less likely when joining the materials.

- Lower tooling costs: MarkPeri RF sealing equipment operates with less arcing and power than conventional welders, so the tooling will last longer and require less maintenance. These advantages translate into increased savings for frequently manufactured products.

- Increased energy efficiency: Because of the minimal heat, radio frequency sealers require significantly less energy than conventional welding machine models, resulting in increased savings on your utility bills and a higher company bottom line.

WHY CHOOSE MARKPERI FOR ALL OF YOUR SEALING NEEDS

For more than 34 years, we’ve been pushing the envelope in developing increasingly effective RF sealing machines and technology. It’s our goal to build long-term relationships with customers in the automotive, industrial manufacturing and medical industry by delivering cost-effective and efficient solutions. Along with our full selection of RF welders and sealers, we also carry an array of economical used and rebuilt product options.

When you partner with MarkPeri, you benefit from superior product knowledge, customer service and live technical support. Additional advantages of ordering RF sealers from us include:

- In-house service department with over three-quarters of a century industry experience

- Complete retrofit capabilities as well as fast and effective rebuild and reconditioning

- Multiple payment options and flexible financing for qualified customers

- Available two-year and three-year extended warranty programs for all rebuilt systems

- Wide variety of sealer parts, shuttles, turntables and indexing equipment

Ready to take your plastic joining operation to the next level? Give us a call or connect via email to inquire about our innovative line of MarkPeri sealing equipment today.