Tarpaulin RF Welding Machines

Get a Quote for a Tarp Welder Click to Call 516.208.6824

When you need secure tarpaulin seams for your trucks and other applications, finding the right equipment is critical. You might realize that relying on sewn seams to keep your truck tarps locked down may not be the best approach. For the best results, you will want to look at hot seam tarpaulin welders that create a reliable bond for your tarps you know you can count on day after day for all of your business applications.

MarkPeri offers industry-leading tarpaulin welders that are durable, reliable and effective. Contact us directly today so we can learn more about your specific equipment needs and provide a lasting solution.

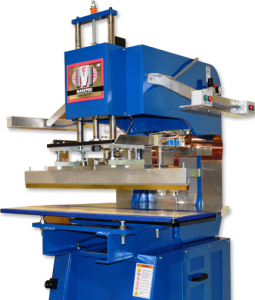

RF Bar Welders for Tarpaulin Heat Sealing

If you have struggled to find the right tarpaulin welder for your needs, consider a quality Radio Frequency bar welder. Businesses throughout the country look to RF bar welders when they need a reliable tarpaulin sealing machine.

This form of industrial tarp welder equipment operates similarly to your microwave. However, instead of heating water or food, an RF bar welding machine heats a metal bar and the fabric of your tarp by exciting the molecules within with radio waves.

This excitation gives those molecules a negative electrical charge thousands of times per second, creating intense heat friction that allows the bar to apply pressure and create an incredibly tight seal. This bonds your tarp’s fabric as tightly, or more tightly, than if you had sewn it down — just much quicker and more efficient.

Bar welders are ideal for long liner and tarp seams consisting of materials like PVC, vinyl, mesh and other polyethylene materials. Some welding techniques use two bars to eliminate a second step in the manufacturing operation and maximize efficiency.

Types of Bar Welders for Industrial Tarp Welding

MarkPeri offers a comprehensive range of bar welders to meet the unique needs of your application. Our bar welders range in size from 36-72 inches to provide flexibility and diversity in manufacturing. These systems also come in 6-20 kilowatt power capacities for wider-width materials.

Our engineers will also help you create a bar welding system to maximize your operation’s efficiency and production. We can perform customized mounting of controls and other options, like installing attachments to punch out grommets before welding.

If you’re looking for a reliable bar welder at an economical price, consider one of MarkPeri’s rebuilt or used machines. Our highly skilled technicians and engineers specialize in restoration and repair, allowing us to offer pre-owned equipment at prices dramatically lower than new models. We refurbish all our welding systems to perform like new, ensuring the machinery will provide many years of reliable service.

We also offer repair services to keep your machine running at full speed while minimizing unwanted downtime.

The Benefits of RF Bar Welders for Tarp Welding

Why choose RF Bar Welders over other industrial tarp welding equipment? We think you will find that RF bar welders have numerous advantages. Other tarpaulin heat welders may damage your tarp plastic. However, most tarps and liners are fairly resistant to RF heating damage, meaning you are more likely to get a clean seal. We can also apply a coating of polytetrafluoroethylene (PTFE) to the bar surface to make sure the plastic does not adhere to it.

RF bar welding is a more eco-friendly approach to tarpaulin sealing as the heating and sealing process does not generate any toxic smoke. In the end, many businesses prefer using the RF bar welder as their tarpaulin welding machine because the end product looks and feels smooth, streamlined and high-quality.

Additional benefits of using RF bar welding equipment include:

- Minimizing damage: Our welding equipment outperforms traditional systems by delivering controllable and consistent power output throughout the welding cycle. This consistency means you get enhanced seal strength without needing to add an extra process. Better strength and improved consistency also translate to less product damage.

- Improving energy efficiency: Our bar systems require significantly less power than traditional welding systems, providing significant cost savings in manufacturing. Many of our systems come with connectors that monitor energy output during the welding cycle.

- Delivering superior quality: Consistency in power and more durable welds result in higher quality work and optimal appearance. RF welding is significantly stronger than sewing and offers increased water resistance for outdoor applications. In most cases, the weld is stronger than the material.

Why Choose MarkPeri as Your Tarp Seam Sealer Equipment Provider?

When you select MarkPeri for bar welders and your tarpaulin welding needs, you’ll enjoy many advantages, including:

- Unsurpassed expertise: Our service department is among the most knowledgable and skilled in the industry, with many decades of combined experience. We’ll help you select the most practical and efficient welding solution for your specific application.

- Flexible payment options: Our staff helps qualified customers design the perfect financing plan to fit their company’s budget.

- Comprehensive warranties: We offer warranties for all new, used and refurbished systems, providing you peace of mind for the equipment you buy.

- Extensive parts inventory: We keep a vast parts inventory on hand for your requirements, whether you need to replace a part or make a machine upgrade.

- Repair services: Our field service team consists of highly skilled, professional technicians who understand how to repair and maintain all types of RF welding equipment.

Contact MarkPeri for Tarpaulin Welders Today

If you are interested in an RF bar welder for your tarpaulin welding machine needs, we have a wide variety of affordable and effective RF bar welder options to choose from at 3KRF, a division of MarkPeri International.

Why us? We have been in the RF welding business for over 35 years, providing the highest quality machines when it comes to RF sealing equipment and systems. We have a range of machines to meet both your budget and your goals for your business. We believe our combination of experience, flexible solutions and commitment to customer satisfaction is the key to our success and is why you will want to work with us now and in the future for your RF welding applications.

For more information on finding the right tarpaulin sealing machine for your business, contact us now.